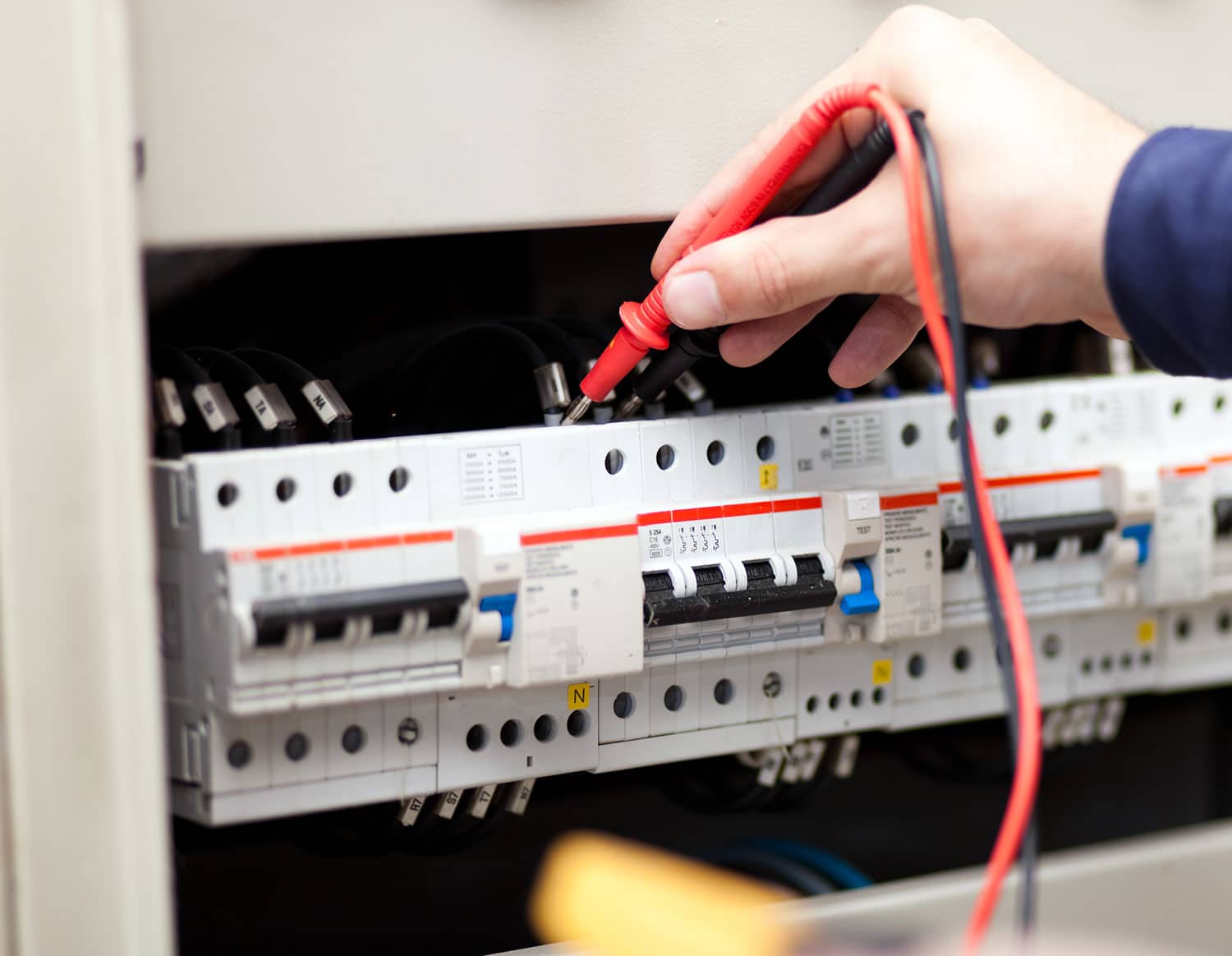

Testing & Inspecting – What Tests Are Carried Out?

See below the various types of electrical safety tests that are carried out on a day to day basis whilst testing and inspecting:

High Voltage Test (Dielectric Voltage-withstand Test)

This test is carried out by applying a significantly higher than operating voltage to the device under test. In this test, the insulation of a product, stressed to a greater extent than under normal operating conditions, should not be breached for the product to pass. In most cases, the device is stressed to twice its normal operating voltage. During type testing, i.e. testing during designing a product or for a double insulated product, however, much larger voltage may be applied. For all electrical products, the high voltage test is a universal test, meaning that every unit should pass before it can be used.

Insulation Resistance Test

This test is to measure the total resistance of a product’s insulation by applying a voltage of 500 V – 1000 V for low voltage systems. The acceptable value of resistance for a product to pass an insulation resistance test is relative. They can be quite different for one motor or machine tested three days in a row, yet not mean bad insulation. What really matters is the trend in readings over a time period, showing lessening resistance and warning of coming problems. The insulation resistance test is not a substitute for the high voltage test. Many standards and safety agencies have specified this is a universal test for all products. This test may also be carried out after every maintenance procedure or repair.

Earth Continuity Test

This test is performed by measuring the resistance between the third pin (ground) and outside metal body of the product under test. The maximum acceptable value is generally 0.5 ohms although certain standards may specify 0.1 ohms. This test is generally carried out at a slightly higher current (e.g. 25–60) so that the ground bond circuit maintains safe voltages on the chassis of the product, even at a high current, before the circuit breaker trips. This test is essential so that the product does not cause an electric shock resulting from insulation failure. In India current specified is 16 A so the test is done at double of the current i.e. 32 A.

Leakage Current Test (Line Leakage Test)

This test is to measure the undesirable leakage current that flows through or across the surface of the insulation or the dialetric of a capacitor. This test is generally carried out at 100%-110% of the rated input voltage of the product under test. The maximum acceptable limit of a leakage current is generally 210 micro amperes. At first, this test was mandatory for medical devices only.

Visual inspection:

This is where the electrician carrying out the testing and inspecting will survey the electrical installation before he/she commences with the electrical testing. The visual inspection will highlight broken or cracked devices, where devices may have been installed in the wrong location, or if there have been overloading or over heating problems.

Electrical testing with the use of electrical test meters, including:

Dead testing

Continuity testing: a test to check if there are any badly connected conductors (wires)

Insulation resistance testing: this test is to make sure that the electrical insulation material surrounding the conductors is intact.

Polarity: this test is to check that the connection are connected in the right sequence

Earthing arrangement testing: this check is to make sure that the earthing arrangement complies with regulations and that all connections are sound.

Live testing

Earth fault loop impedance testing: this test is to check that if a fault did occur, that the system meets requirements to cause a disconnection of the supply within the time limit specified

RCD testing: on modern electrical systems RCD’s and RCBO’s are regularly fitted, these devices react to electricity missing from the circuit or installation such as when a person is receiving an electric shock as the electricity passes through his body to the ground (earth).

Electrical Installation Condition Report

The competent person will then issue an Electrical Installation Condition Report (EICR), also known as Periodic Inspection and Testing Report (PIR), detailing any observed damage, deterioration, defects, dangerous conditions and any non-compliances with the current safety standard which might give rise to danger.

If anything dangerous or potentially dangerous is found whilst testing and inspecting, the overall condition of the electrical installation will be declared to be ‘unsatisfactory’, meaning that remedial action is required without delay to remove the risks to those in the premises. A typical classification of faults found is:

- C1 – Danger present. Risk of injury. Immediate remedial action required.

- C2 – Potentially dangerous – urgent remedial action required.

- C3 – Improvement recommended.

- FI – further investigation required.

Gary Price

Orrell Electrics Emergency Electricians Liverpool